Imagine your electronic devices being like magnets, attracting dust and lint with a relentless force.

Just like a superhero swoops in to save the day, anti-static agents come to the rescue in coatings to repel these pesky particles.

But what exactly are these agents made of, and how do they work their magic?

Let’s uncover the secrets behind these invisible shields that keep your surfaces clean and pristine.

The Role of Anti-Static Agents

Anti-static agents play a crucial role in coatings by preventing the buildup of static electricity. When you apply coatings to various surfaces, especially in industries like electronics, automotive, or packaging, static electricity can be a significant issue.

Imagine a scenario where static electricity builds up on a coated surface, attracting dust, lint, or even causing sparks that could lead to hazardous situations. This is where anti-static agents step in to save the day.

Mechanism of Action

Understanding how anti-static agents work involves delving into their molecular interactions within the coating material. These substances function by altering the surface properties of the coating to prevent the accumulation of static charges.

Here’s a closer look at the mechanism of action:

- Disruption of Charge Build-Up: Anti-static agents contain compounds that interfere with the buildup of static charges on the coating’s surface.

- Improved Conductivity: By enhancing the material’s conductivity, these agents facilitate the dissipation of any static charges that do form, preventing them from accumulating.

- Surface Modification: Anti-static agents modify the coating’s surface to make it more antistatic, reducing the likelihood of static electricity generation and enhancing overall performance.

Types of Anti-Static Agents

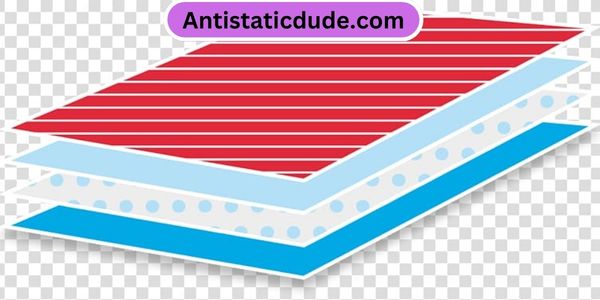

To further explore the realm of anti-static agents, it’s essential to differentiate between the various types available in the market. There are primarily two types of anti-static agents commonly used in coatings: external anti-static agents and internal anti-static agents.

External anti-static agents are additives that can be applied topically to the surface of the coating. These agents work by forming a thin layer on the surface, which helps to dissipate any static charges that may build up. Common examples of external anti-static agents include quaternary ammonium compounds and long-chain fatty acid esters.

On the other hand, internal anti-static agents are additives that are incorporated into the coating formulation itself. These agents are evenly distributed throughout the coating, providing long-lasting anti-static properties. Internal anti-static agents often consist of conductive materials like carbon black or metallic compounds.

Both types of anti-static agents play a crucial role in maintaining the desired anti-static properties of coatings, ensuring a static-free environment in various applications.

Benefits of Using Anti-Static Agents

Using anti-static agents in coatings offers several significant advantages in various applications. These benefits make them a valuable addition to a wide range of products. Here are three key advantages to consider:

- Prevents Dust Accumulation: Anti-static agents help reduce the build-up of dust particles on coated surfaces by neutralizing static charges. This is particularly beneficial in industries such as electronics, automotive, and packaging, where dust accumulation can impact product quality and performance.

- Enhances Safety: By dissipating static charges, anti-static agents can help prevent static electricity-related accidents, such as sparks that could lead to fires or explosions. This is crucial in environments where flammable materials are present, improving overall safety measures.

- Improves Surface Appearance: Coatings containing anti-static agents tend to have a cleaner and more aesthetically pleasing appearance as they repel dust and dirt particles. This can benefit various applications, including in the automotive industry where a polished and dust-free surface is desired.

Application Considerations

Consider key factors when applying coatings with anti-static agents to ensure optimal performance and effectiveness. Proper application is crucial in maximizing the benefits of anti-static agents in coatings. One key consideration is the surface preparation before applying the coating. Ensure the surface is clean and free of any contaminants to promote adhesion and uniform coverage. Additionally, the environmental conditions during application, such as temperature and humidity, can impact the effectiveness of the anti-static agent.

Here is a table highlighting some application considerations for coatings with anti-static agents:

| Application Considerations | Description |

|---|---|

| Surface Preparation | Ensure the surface is clean and free of contaminants. |

| Environmental Conditions | Optimal application temperature and humidity levels. |

| Mixing Ratios | Follow manufacturer’s guidelines for correct ratios. |

| Application Methods | Choose appropriate method for even coverage. |

| Curing Time | Allow sufficient time for the coating to cure properly. |

Frequently Asked Questions

Are There Any Potential Side Effects or Risks Associated With Using Anti-Static Agents in Coatings?

When using anti-static agents in coatings, be cautious of potential side effects or risks. It’s essential to research and understand any possible negative impacts on the coating’s performance or the environment before application.

Can Anti-Static Agents Be Used in All Types of Coatings, or Are There Limitations on Their Compatibility?

You can generally use anti-static agents in various coatings, but compatibility can vary. It’s essential to check if the specific coating you’re using is compatible with the anti-static agent to ensure optimal performance.

How Long Do Anti-Static Agents Typically Remain Effective in Coatings Before Needing to Be Reapplied?

Typically, anti-static agents in coatings remain effective for varied durations before needing reapplication. Factors like environmental conditions and usage influence their longevity. Remember to monitor performance and follow manufacturer guidelines for optimal results.

Are There Any Environmental Concerns or Regulations to Consider When Using Anti-Static Agents in Coatings?

When using anti-static agents in coatings, it’s crucial to consider environmental concerns and regulations. Ensure you comply with guidelines to minimize impact. Stay informed about any restrictions and choose eco-friendly options whenever possible.

Are There Any Special Considerations or Precautions to Take When Applying Coatings With Anti-Static Agents in Certain Industries or Applications?

When applying coatings with anti-static agents in specific industries or applications, always adhere to recommended guidelines. Monitor compatibility with substrates, ensure proper ventilation, and follow safety protocols. Stay informed about potential risks and implement necessary precautions for optimal results.

Conclusion

In conclusion, anti-static agents play a crucial role in coatings by reducing the build-up of static electricity. They work by either absorbing moisture or forming a conductive layer on the surface.

Different types of anti-static agents offer various benefits, such as improved safety, cleanliness, and performance. When considering applying anti-static agents to coatings, it’s important to choose the right type based on the specific requirements of the application.

Leave a Reply