When it comes to safeguarding sensitive electronic components, the use of anti-static packaging is crucial. But how do you ensure you’re doing it correctly to prevent damage?

Understanding the proper techniques and materials is key. From selecting the right anti-static materials to implementing secure handling practices, each step plays a vital role in maintaining the integrity of your electronics.

Stay tuned to discover the essential guidelines for effectively utilizing anti-static packaging and safeguarding your valuable equipment.

Importance of Anti-Static Packaging

Understanding why anti-static packaging is crucial can help prevent damage to sensitive electronic components during handling and transportation. When electronic components aren’t properly protected, they can easily be damaged by electrostatic discharge (ESD), which can result from simple actions like touching or moving the components. Anti-static packaging materials are designed to dissipate static electricity and prevent it from building up on the surface of the components.

Using anti-static packaging is essential because it ensures that your electronic devices remain safe from ESD-related damage. By utilizing these materials, you create a protective barrier that reduces the risk of static electricity harming the components. This is particularly important in environments where static electricity is more likely to occur, such as workplaces with low humidity levels or when electronic components are being shipped over long distances.

Types of Anti-Static Materials

To effectively protect sensitive electronic components from electrostatic discharge (ESD), it is crucial to be aware of the various types of anti-static materials available for packaging. Different materials offer varying degrees of protection against static electricity. Here are some common types of anti-static materials used in packaging:

| Material Type | Description | Common Uses |

|---|---|---|

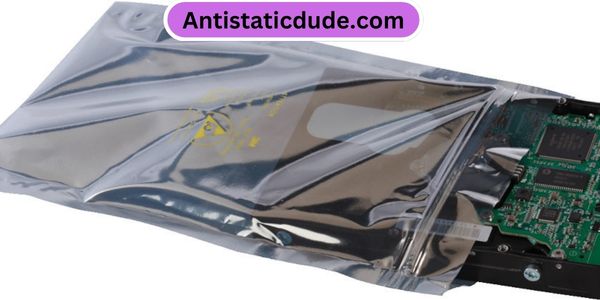

| Anti-Static Bags | These bags are designed to dissipate static electricity and protect sensitive components such as circuit boards, hard drives, and computer parts. | Packaging electronic components during storage or transportation. |

| Anti-Static Foam | This foam is specially treated to prevent the buildup of static charges and provide cushioning for delicate items. | Lining shipping boxes to protect fragile electronic devices during transit. |

| Anti-Static Bubble Wrap | Bubble wrap with anti-static properties that safely wraps around items to shield them from static electricity. | Wrapping electronic gadgets like smartphones and tablets before shipping or storage. |

Understanding the characteristics and purposes of these materials enables you to make informed decisions when choosing the most suitable anti-static packaging for your electronic goods.

Proper Handling Techniques

When handling electronic components, ensure you ground yourself properly to prevent static discharge. Before touching any sensitive parts, touch a grounded metal object to discharge any built-up static electricity from your body.

Additionally, when working on electronics, avoid wearing clothing made of static-prone materials like wool or synthetic fabrics. Instead, opt for antistatic wrist straps or heel straps that keep you grounded throughout the process.

When moving components or circuit boards, hold them by the edges to avoid damaging any delicate parts or leaving behind fingerprints that could interfere with their performance. Furthermore, always store electronic items in antistatic bags or containers when not in use to protect them from potential static damage.

Remember to handle electronic components with care, as even a small static discharge can cause irreparable harm. By following these proper handling techniques, you can ensure the longevity and functionality of your electronic devices.

Steps to Package Electronics

Begin by carefully placing the electronic components inside antistatic bags or containers to ensure they’re protected from any static damage during storage or transportation. Make sure the bags or containers are sealed properly to maintain their antistatic properties.

Next, cushion the packaged electronics with appropriate materials such as bubble wrap or foam to provide shock absorption and prevent any physical damage. Place these cushioned items in sturdy cardboard boxes, ensuring there’s no empty space for the items to move around during transit. Seal the boxes securely with packaging tape to keep the contents safe and protected.

Label the boxes clearly with appropriate handling instructions and identification labels to facilitate easy identification and handling. Finally, store the packaged electronics in a dry and cool environment away from direct sunlight or sources of heat to maintain their quality until they’re ready for use.

Best Practices for Storage

Consider utilizing appropriate storage conditions to maintain the quality and longevity of your packaged electronics. When storing electronics, it’s crucial to keep them in a controlled environment with stable temperature and humidity levels. Extreme temperatures and humidity can damage electronic components and lead to malfunctions. Aim to store your electronics in a dry, cool place away from direct sunlight and moisture.

Furthermore, it’s advisable to store electronics away from any sources of electromagnetic interference, such as motors or power cables, as these can cause disruptions in the devices’ functionality. Additionally, avoid stacking heavy items on top of electronic devices to prevent physical damage.

Organize your stored electronics systematically, ensuring that each item is easily accessible when needed. Labeling boxes or shelves can help you quickly locate specific electronics without causing unnecessary handling or potential damage.

Frequently Asked Questions

Can Anti-Static Packaging Be Reused Multiple Times, or Is It Meant for One-Time Use Only?

Anti-static packaging can typically be reused multiple times as long as it remains effective in preventing static electricity damage. Check for wear and tear. When in doubt, replace with new packaging for optimal protection.

Is Anti-Static Packaging Necessary for All Electronic Devices, or Are There Certain Types of Electronics That Do Not Require It?

Anti-static packaging is essential for protecting all electronic devices from static electricity. While some electronics may be less sensitive, it’s safest to use anti-static packaging for all devices to prevent damage.

How Long Can Electronics Be Safely Stored in Anti-Static Packaging Before They Need to Be Removed and Used?

Store electronics in anti-static packaging for up to a year, then remove and use them. Extended storage can lead to moisture buildup and potential damage. Regularly check devices stored in anti-static packaging to ensure optimal performance.

Are There Any Specific Environmental Conditions That Can Affect the Effectiveness of Anti-Static Packaging?

In specific environmental conditions, the effectiveness of anti-static packaging can be compromised. Factors like high humidity or temperature extremes may diminish its protective properties. Be mindful of these influences to maintain your packaging’s efficacy.

Are There Any Alternative Methods or Materials That Can Be Used in Place of Traditional Anti-Static Packaging for Electronics?

When considering alternatives to traditional anti-static packaging for electronics, explore options like conductive bags, static shielding bags, or moisture barrier packaging. These materials can provide effective protection against electrostatic discharge, ensuring your electronics stay safe.

Conclusion

Remember, using anti-static packaging is crucial in protecting your electronics from damage caused by static electricity.

By understanding the importance of anti-static materials, proper handling techniques, and following the steps outlined for packaging and storage, you can ensure that your electronic devices remain safe and functional.

Don’t overlook the importance of anti-static packaging – it can make a significant difference in prolonging the lifespan of your valuable electronics.

Leave a Reply